How Wrap-Around Label Machines Improve Packaging Line Speed & Productivity

04/01/2025

Labeling machines really speed up your packaging line. They put labels on accurately and quickly, boosting how much you can produce. This method, simpler than pick-and-place approaches, excels in the round bottle sector but suits almost any container type. It cleverly uses all the available space to show off your brand while still following all the rules for UPC codes.

Big or small, businesses can easily switch from doing things by hand to using automation. This saves resources and makes things much easier. Businesses save money and improve efficiency with a simple one-label-per-item system. This works great in various sectors. Wrap-around technology: It really makes production lines fly! Let's see how.

Boosting Speed with Wrap-Around Technology

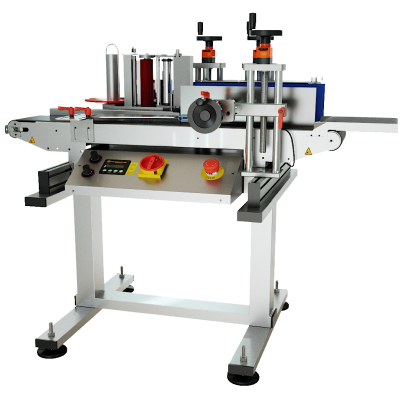

Wrap-around label machines, like those offered by GLOBALTEK®, swiftly apply labels to various containers. By rolling labels directly onto the surfaces, these systems simplify labeling processes compared to traditional methods. They're as effective as shrink-wrap but less complicated and dominate in packaging round bottles.

Yet, their versatility extends beyond just cylindrical shapes; almost any container can be labeled efficiently with wrap around label machines. This approach boosts speed on the production line by eliminating complex steps involved in manual or pick-and-place methods, making it a go-to for enhancing productivity across different industries.

Enhancing Accuracy in Label Placement

Accurate label placement is crucial for the look and function of your product. Let's break down how wrap-around label machines improve this aspect.

- Enhanced Precision: Wrap-around labelers use advanced sensors to detect containers' edges. This ensures each label aligns perfectly with every container, eliminating crooked labels. By maintaining consistency, these machines reduce waste from misaligned labels. They increase consumer trust in your brand by ensuring products always look professional on shelves.

- Reduced Manual Labor: These machines automate the labeling process, requiring fewer staff members for operation and oversight. Reducing manual handling also minimizes human error in label applications. This automation leads to more consistent results across thousands of products. Furthermore, employees can focus on other important tasks that improve productivity.

- Accelerated Changeover Times: Quick adjustment features allow for rapid changeovers between different product sizes or shapes. Machine downtime is significantly decreased thanks to intuitive design elements. These fast transitions maintain line speed without sacrificing accuracy. Efficient changeovers support a versatile packaging line capable of handling various SKUs efficiently.

Reducing Downtime with Seamless Operation

Reducing downtime in a packaging operation is about ensuring smooth, continuous activity. This step is crucial for keeping up with market demands and maintaining high customer satisfaction.

- Minimized Errors: Automatic label applicators significantly reduce the number of mislabeled products. When labels are placed correctly every time, you avoid the setbacks that come from discarding or reworking items due to labeling mistakes. Moreover, consistent accuracy keeps your brand's image polished across all products.

- Quick Changeovers: Opt for machines equipped with automated adjustment features for fast label changes between production runs—this capability cuts down significant downtime often seen during manual changeovers, allowing seamless transitions among different product lines without major delays, thus enhancing line uptime and output consistency throughout operations.

- Reduced Waste: Precise application via advanced machinery leads directly to less waste since there's a minimal chance of incorrect labeling requiring disposal or extra work on already finished goods; this approach not only conserves materials but also saves money by cutting down on unnecessary resource use and waste management efforts while contributing positively towards sustainability goals within manufacturing processes.

Increasing Productivity Across Packaging Lines

Wrap-around label machines minimize errors by automating data collection, a critical factor in avoiding delays. These devices verify order numbers and ensure proper routing with embedded barcode scanners, cutting down human mistakes significantly. Another innovative feature is branding bands that can be customized with logos or product details.

Perfect for items like clamshells used in the food sector. In addition, these branded bands support inline printing for swiftly updating batch information or expiration dates just before packaging. Automation stands out as it addresses worker shortages efficiently while enhancing production reliability and speed without needing many employees.

For instance, automated counting and stacking systems specifically designed for multipacks demonstrate how technology can replace manual tasks effectively. Minimizing waste is another advantage offered by wrap-around label machines since they utilize custom-sized boxes to reduce the use of unnecessary packing materials. By licensing plate bundled orders beforehand, this method also eradicates potential order mixing or system blockages during conveyance.

In essence, integrating such sophisticated machinery not only speeds up processes but also reduces costs associated with labor turnover and training. This is a crucial consideration given today's industry challenges.

Ensuring Consistent Quality and Brand Image

Ensuring consistent quality and brand image in your labeling process is crucial for maintaining a strong market presence. Global standards demand precision, reliability, and visual appeal to attract customers.

- Product Size and Shape: GlobalTek® understands that fitting the label perfectly matters a lot. A label too big creates overhangs; one too small leaves unattractive gaps. Properly sized labels improve looks and functionality by avoiding these issues entirely. Consistent application means each product on the shelf matches its neighbor perfectly.

- Quality of Labels: High-quality materials make durable labels essential for sustained branding power as products move through tough shipping conditions or sit on shelves under harsh lights. No tearing, fading, or peeling keeps your brand's look crisp from production line to customer hands—crucial for lasting impressions.

- Appropriate Labeling Equipment: Tailored equipment avoids bottlenecks in high-volume operations. For smaller setups, it delivers precision without unnecessary complexity. Modular designs offer flexibility, allowing upgrades without disruption, making sure every bottle can, or container exits with consistency at any volume, and meeting both current needs and future growth seamlessly.

Streamlining Workflow for Higher Output

Streamlining your workflow enhances productivity significantly. By integrating automatic labelers like GLOBALTEK® into your packaging process, you automate labeling tasks. This automation allows staff to direct their attention to other essential duties, boosting the overall output of your setup.

This efficiency leads to increased production and shipping volumes, directly influencing revenue growth. In addition, automated labeling machines play a critical role in improving quality control by minimizing manual errors such as misalignment or incorrect placement of labels. These high-precision machines ensure accurate barcode and QR code application every time, which is crucial for inventory management and avoiding supply chain disruptions.

Investing in state-of-the-art labelers adapts well across business scales. From small boutiques to large factories. Due to their flexibility in handling various bottle sizes and shapes with pinpoint accuracy.

Such versatility prevents the need for multiple specialized units catering to different product lines, streamlining operations further.

Choosing the right tools for your packaging line significantly boosts speed and productivity. GLOBALTEK®'s inline automatic wrap-around labeler does just that. It ensures precision in application, reducing waste and downtime.

This machine fits seamlessly into existing lines, enhancing efficiency without massive overhauls. With quick setup times and easy operability, it stands out as a smart investment for improving packaging processes. Businesses benefit from increased output with consistent quality, making this labeler a critical component in optimizing production performance.

Comments

No posts found